Research

The CFD & HSE Simulation Research Group utilizes advanced numerical techniques to address critical challenges in industrial process safety, occupational health and safety, indoor air quality, air pollution, multiphase flows, chemical reaction engineering, porous scale modelling, and public health. Through rigorous numerical simulations, we provide in-depth understanding and predictive capabilities for complex phenomena across these interconnected domains. Furthermore, we are increasingly incorporating AI/ML algorithms with our numerical data obtained to provide enhanced critical insights, achieve more accurate predictions, faster analysis, and optimized solutions for a wide spectrum of vital industrial and public health issues. This interdisciplinary approach fosters a deeper understanding of complex phenomena and facilitates the development of more effective strategies for enhancing safety, health, and environmental protection.

Industrial Process Safety

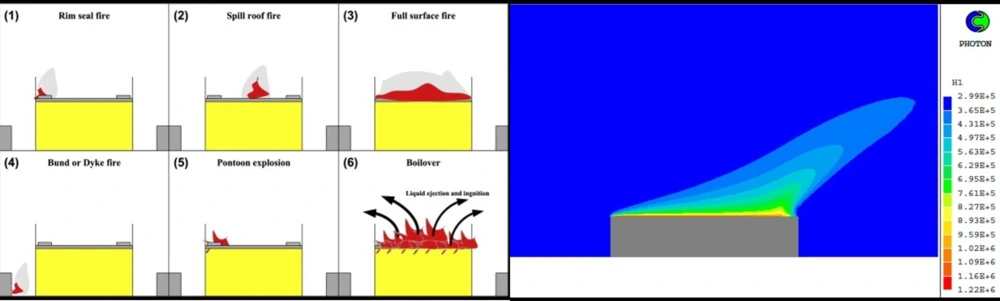

To ensure process safety in the Oil & Gas and Petrochemical industries, we employ a combination of advanced Computational Fluid Dynamics (CFD) tools (Fig.1) and comprehensive Process Hazard Analysis (PHA) methods. Our PHA framework includes established techniques such as checklists, Quantitative Risk Assessment (QRA), HAZOP (Hazard and Operability Study), STAMP (Systems-Theoretic Accident Model and Processes), and STPA (Systems-Theoretic Process Analysis), among others. This powerful combination enables us to simulate and thoroughly analyze potential hazards, including the dispersion of flammable or toxic materials from a release, the progression dynamics of explosions, and the performance of safety barriers and ventilation systems

Figure1:a) Potential tank fire scenarios [1] and b) Enthalpy contours around the tank on fire obtained using the commercial CFD software PHOENICS [2].

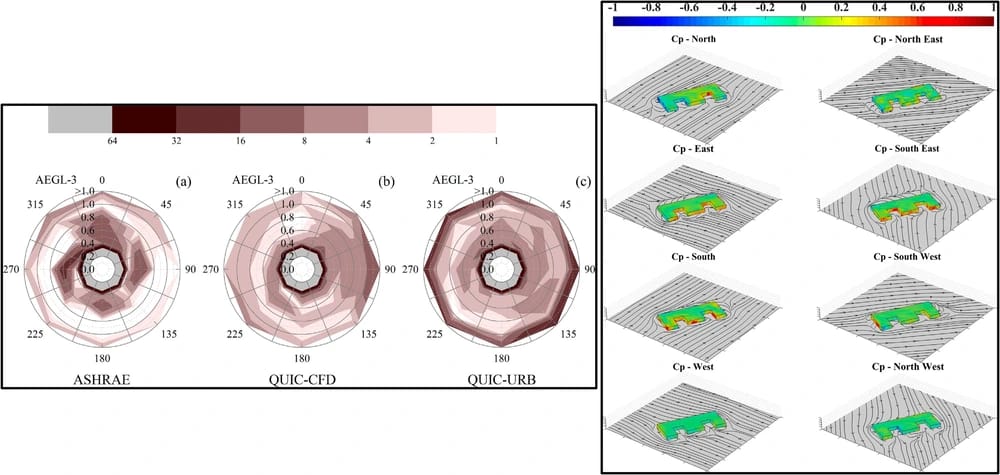

A critical consideration, often posing a higher risk, is the potential for toxic releases occuring outdoors to impact occupants withing nearby indoor environments. The ingress and subsequent entrapment of hazardous gases indoors can lead to significantly accelerated accumulation, potentially reaching lethal dosages more readily than in open-air conditions (Fig. 2). Despite this pronounced risk, there remains a notable lack of data in empirical data and comparative studies regarding appropriate modelling techniques and effective mitigation strategies for indoor exposure. Consequently, we utilize advanced CFD techniqeus to specifically investigate phenomena such as toxic building ingress and to perform rigorous risk assessments based on dose-response methodologies. The proposed methodology will serve as a guide for the improvement of relevant risk assessment tools and future studies.

Figure2:a) Distribution of the AEGL-3 values, for all building rooms, at different wind directions and for the CD-HVAC off-scenario, radius corresponds to the AEGL value and the colour represents the number of rooms with this value for: (a)ASHRAE model. (b) QUIC-CFD model and (c) QUIC-URB model and b) Surface streamlines and Cp for “D5”and 8 different wind directions calculated by QUIC-CFD [3].

Furthermore, we harness the power of AI and ML algorithms to extract deeper insights from our numerical data, enabling advanced hazard identification, predictive risk modeling, and sophisticated scenario analysis. By modelling the fluid dynamics of critical events, we contribute directly to the design of inherently safer processes and developing effective risk mitigation strategies. The strategic integration of AI and ML significantly elevates our process safety capabilities, resulting in safer operations, substantial risk reduction, and enhanced environmental stewardship. This data-driven approach paves the way for a more proactive and effective safety management system.

Occupational Health and Safety (OH&S)

In the realm of occupational health and safety, we utilize CFD to assess worker exposure to airborne contaminants, heat stress, and other physical hazards within workplaces (Fig. 3). Our simulations can optimize ventilation designs, evaluate the effectiveness of personal protective equipment, and inform strategies to minimize occupational risks, ultimately fostering healthier and safer working conditions. In addition, via online surveys and questionnaires, we are trying to evaluate the common occupational health hazards among workers for different industrial sectors (e.g. oil & gas, drilling operations and exploration, petrochemicals, manufacturing, etc.) and study their health effects and risks [4]. Moreover, we study the prediction of safety factors on safety compliance to substantial accident risks and provide meaningful and practical recommendations [5]. This will allow us to enhance the safety compliance level and identify essential risks, improve safety culture, comply with safety rules and procedures.

Figure3:Pulling out of drill hole, Turner Valley oil field, Alberta Provincial Archives of Alberta, P1983.

Indoor Air Quality

Our research on Indoor Air Quality (IAQ) focuses on understanding and predicting the transport and distribution of pollutants within enclosed spaces, such as offices, hospitals, and residential buildings. We investigate the impact of ventilation systems, meteorological conditions, filtration technologies, and indoor sources of contamination on air quality, aiming to develop strategies for creating healthier and more comfortable indoor environments

![Comparison of indoor measured and predicted PM2.5 levels for a) all the collected data and b) the dust storm period. Also, the scatter plots of measured versus predicted mass concentration c) in full graph scale and d) zoom graph scale including the additional linear fitting for FIT (red solid line) and MERV14 (blue solid line) scenarios. The black solid line indicates perfect agreement, while the black dashed lines represent the fraction of predictions within a factor of two of measurements (FAC2). The light grey shaded areas represent in (a) the period of the selected dust event and in (c) the zoom area [6].](/_next/image?url=%2Fresearch%2FFigure_4.webp&w=3840&q=80)

Figure4:Comparison of indoor measured and predicted PM2.5 levels for a) all the collected data and b) the dust storm period. Also, the scatter plots of measured versus predicted mass concentration c) in full graph scale and d) zoom graph scale including the additional linear fitting for FIT (red solid line) and MERV14 (blue solid line) scenarios. The black solid line indicates perfect agreement, while the black dashed lines represent the fraction of predictions within a factor of two of measurements (FAC2). The light grey shaded areas represent in (a) the period of the selected dust event and in (c) the zoom area [6].

Dust storms not only affect the health of those outdoors, but also the people living indoor as the PM infiltrates through the buildings. Despite the fact that Middle East Area (MEA) countries are suffering from frequent dust storm events, there is still a lack of knowledge regarding the health assessment in indoor environments (e.g. houses and commercial buildings) and the design of appropriate actions and mitigation measures in order to minimize the potential health effects. We are using advanced CFD techiques to predict the Particulate Matter (PM) building infiltration (Fig. 4). More specifically, a combination of CFD and multi-zone modes could be used along with available measurements from Low Cost Sensors (LCS). This combination is superior for more realistic predictions of airflow and pollutant transport in large buildings. Some initial work has already be done [6] and extension of the work for buildings in an University Campus will be arranged to improve the capabilities of the above mentioned models by providing better correlations for the particle filter efficiency and distribution size. These correlations will be produced by combining the obtained prediction with measurement PM data in buildings at MEA.

Air Pollution

To tackle air pollution, we harness the power of CFD. Our models simulate how pollutants from diverse sources—including industrial facilities, vehicular traffic, and even large oil tank fires—disperse throughout the atmospheric environment. These detailed simulations are crucial for understanding the real-world impact of emissions on air quality across different scales. The insights we gain directly support the creation of effective pollution control strategies, enhance urban planning initiatives, and bolster overall environmental management efforts. Beyond standard applications, our expertise extends to employing advanced CFD and other numerical techniques like Monte Carlo methods for predicting hazardous substance release amounts and locations. This unique approach utilizes health observations, offering a powerful alternative to traditional concentration or dosage-based methods (Fig. 5) [7].

![Spatial distribution of the correlation coefficient, J, for health effects observations and 100 iterations using (a) 16, (b) 37, (c) 44, (d) 58, (e) 79 and (f) 100 receptors. The blue cross symbol denotes the real source location [7].](/_next/image?url=%2Fresearch%2FFigure_5.webp&w=3840&q=80)

Figure5:Spatial distribution of the correlation coefficient, J, for health effects observations and 100 iterations using (a) 16, (b) 37, (c) 44, (d) 58, (e) 79 and (f) 100 receptors. The blue cross symbol denotes the real source location [7].

Multi-phase flows

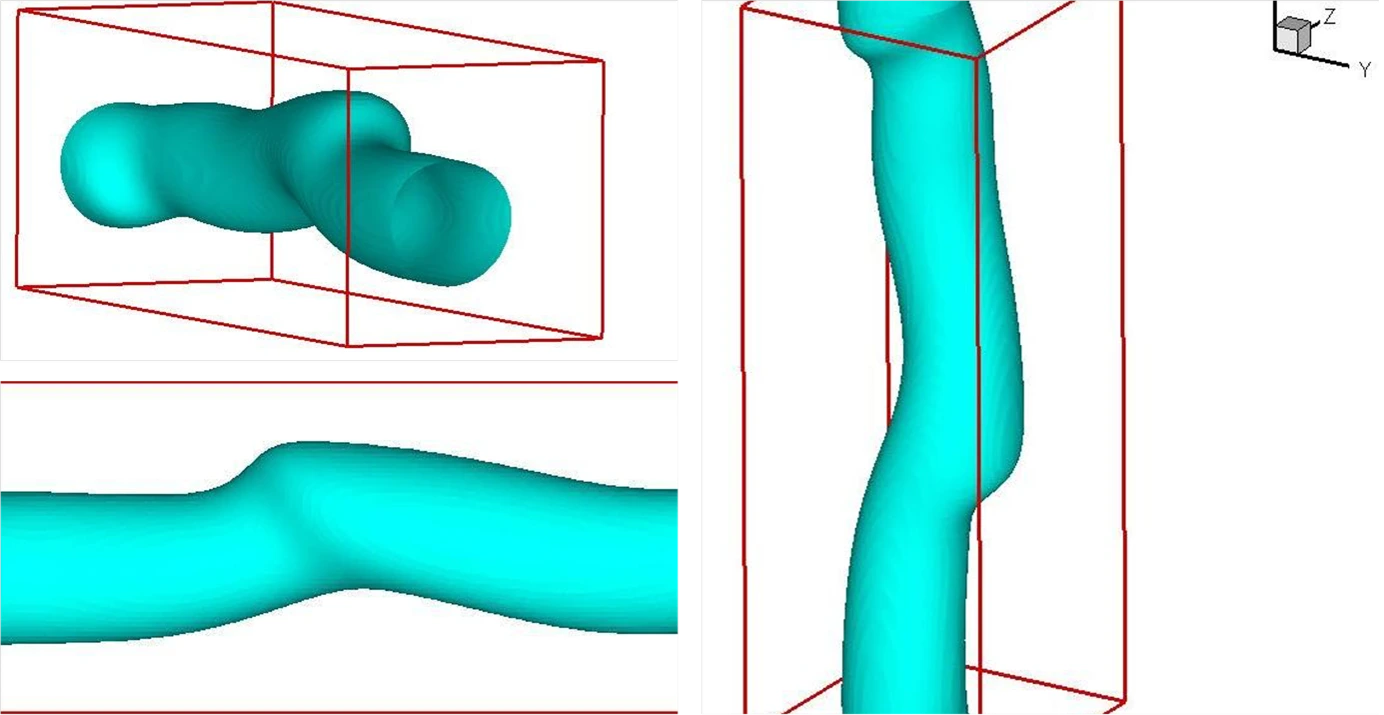

In general, the physical mechanisms that govern the multi-phase fows are characterised by great complexity and the derivation of the appropriate equations for their description is more sophisticated than single-phase flows. The configuration of multiple interfacial regions with or without moving boundaries, along with the presence of discontinuities across the interfacial region due to fluid properties, are only some of the great challenges facing the field of multi-phase flows. The most common category of multi-phase flows are two-phase flows and may be divided, regarding the combination of the two phases, in the following subcategories:gas-liquid flows (e.g. oil-gas mixture transportation), gas-solid flows (e.g. fluidized beds), liquid-solid flows (e.g. slurry transportation) and liquid-liquid flows (e.g oil-water transportation).

Figure6:Interfacial waves were simulated in order to investigate the travelling waves and the type of the waves (e.g. bamboo, snake, corkscrew, etc.).

Our investigations into multiphase flows involve the numerical simulation of systems where multiple phases (e.g., gas-liquid, liquid-solid) interact. This is crucial for understanding and optimizing a wide range of industrial processes, including chemical reactions, separation processes, and energy systems. Our research is focused on, bubble flow, droplet coalescence, single droplet and interfacial waves in pipe flows (Fig. 6) are some of the considered flows.

Chemical Reactor Engineering

In the field of chemical reactor engineering, we apply CFD to gain detailed insights into the flow patterns, mixing characteristics, heat transfer, and reaction kinetics within chemical reactors [8, 9]. This allows for the optimization of reactor design and operating conditions, leading to enhanced efficiency, selectivity, and safety in chemical production. Recently, our group is studying using advanced multiphase CFD models for the Ethylene Epoxidation in chemical reactors (Fig 7).

![Snapshots of solid-phase volume fraction of 2D reactor [9].](/_next/image?url=%2Fresearch%2FFigure_7.webp&w=3840&q=80)

Figure7:Snapshots of solid-phase volume fraction of 2D reactor [9].

Pore Scale Modelling

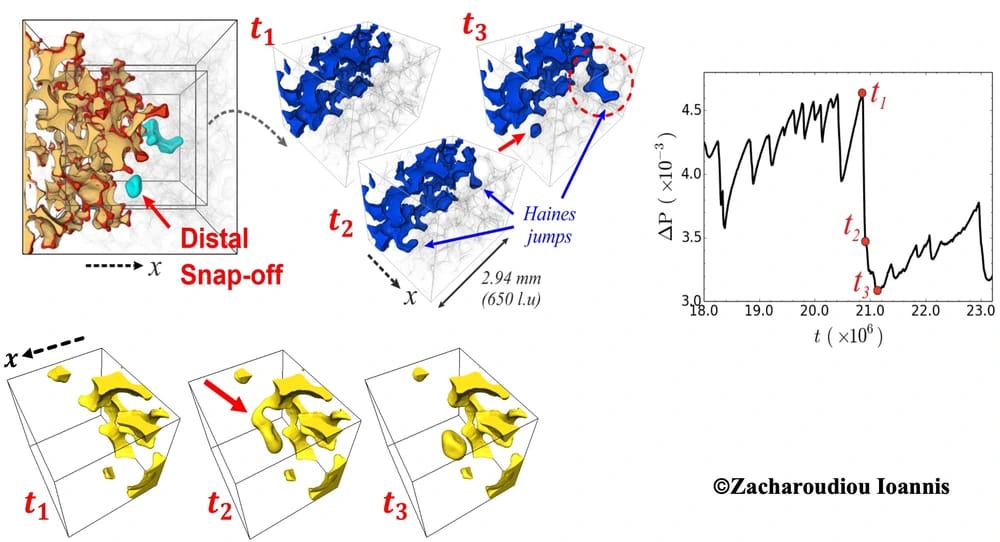

Our research in pore-scale modelling focuses on understanding how fluids and other substances move through porous materials. This research has direct applications in areas like CO2 displacement efficiency, relative permeability, reactive transport, and pore-filling events. By developing and applying numerical models, we gain fundamental insights into flow and transport at the pore scale, which helps us design and optimize larger-scale processes.

Figure8:(a) Fluid rearrangement occurs as a result of jump events, (b) Multiple jump events culminate in distal snap-off (indicated by the red arrow), (c) The same distal snap-off event is depicted from an alternative viewing angle.

Public Health

Finally, our research in public health utilizes CFD to model the spread of airborne diseases, assess the effectiveness of infection control measures in healthcare settings, and evaluate the impact of environmental factors on public health outcomes [10]. More specifically, we also initiated research activities in the field of environmental health and exposure and investigation of biopathogen-fluid interactions in droplets combined with different modes of transmission and contamination using CFD, as well as the location distance between patient and health staff in hospitals and long-term care facilities (LTCF) [11]. This interdisciplinary approach contributes to evidence-based strategies for disease prevention and public health protection.

![A donor-recipient model of transmission of respiratorypathogens within droplets [10]. Through these interconnected research areas, our group strives to advance the understanding of complex fluid flow and transport phenomena and to translate this knowledge into practical solutions that enhance safety, health, and environmental sustainability.](/_next/image?url=%2Fresearch%2FFigure_9.webp&w=3840&q=80)

Figure9:A donor-recipient model of transmission of respiratorypathogens within droplets [10]. Through these interconnected research areas, our group strives to advance the understanding of complex fluid flow and transport phenomena and to translate this knowledge into practical solutions that enhance safety, health, and environmental sustainability.

References

[1]C.D. Argyropoulos, M.N. Christolis, Z. Nivolianitou, N.C. Markatos, A hazards assessment methodology for large liquid hydrocarbon fuel tanks, J. Loss Prevent. Proc. Ind., 25 (2012) 329–335.

[2]C.D. Argyropoulos, M.N. Christolis, Z.S. Nivolianitou, N.C. Markatos, A hazard identification and parametric analysis of toxic pollutants dispersion from large liquid hydrocarbon fuel-tank fires, in: Advances in Energy Research, 2013, pp. 333–371.

[3]C.D. Argyropoulos, A.M. Ashraf, N.C. Markatos, K.E. Kakosimos, Mathematical modelling and computer simulation of toxic gas building infiltration, Process Safety and Environmental Protection, 111 (2017) 687–700.

[4]C. Benson, C. Dimopoulos, C.D. Argyropoulos, C. Varianou Mikellidou, G. Boustras, Assessing the common occupational health hazards and their health risks among oil and gas workers, Safety Science, 140 (2021) 105284.

[5]C. Benson, C.D. Argyropoulos, C. Dimopoulos, C. Varianou Mikellidou, G. Boustras, Analysis of safety climate factors and safety compliance relationships in the oil and gas industry, Safety Science, 151 (2022) 105744.

[6]C.D. Argyropoulos, H. Hassan, P. Kumar, K.E. Kakosimos, Measurements and modelling of particulate matter building ingress during a severe dust storm event, Build Environ., 167 (2020) 106441.

[7]C.D. Argyropoulos, S. Elkhalifa, E. Fthenou, G.C. Efthimiou, S. Andronopoulos, A. Venetsanos, I.V. Kovalets, K.E. Kakosimos, Source reconstruction of airborne toxics based on acute health effects information, Scientific Reports, 8 (2018) 5596.

[8]S. Savvopoulos and C.D. Argyropoulos (2025). “Bridging Experimental Validation and CFD Modeling for Reactor Scale-up”, 2025 AIChE Annual Meeting, Boston, USA.

[9]A. Elhussien, A.E., Chatzimichailidis, S. Savvopoulos, CDArgyropoulos (2025). Integrated CFD and process modeling of ethylene epoxidation in a fluidized-ded reactor: conversion, selectivity, and hotspot mitigation. 2025 AIChE Annual Meeting, Boston, USA.

[10]C.D. Argyropoulos, V. Skoulou, G. Efthimiou, A.K. Michopoulos, Airborne transmission of biological agents within the indoor built environment: a multidisciplinary review, Air Quality, Atmosphere & Health, 16 (2023) 477–533.

[11]P. Vogazianos, C.D. Argyropoulos, C. Haralambous, C.V. Mikellidou, G. Boustras, M. Andreou, V. Silvestros, F. Theofanous, S. Soteriou, I. Gregoriou, A.J. Apostolidou, A. Demetriou, M. Athanasiadou, C. Stylianou, M. Michael, H. Herodotou, D. Alexandrou, O. Kalakouta, Z.D. Pana, Impact assessment of COVID-19 non-pharmaceutical interventions in long term care facilities in Cyprus: Safety improvement strategy, Safety Science, 143 (2021) 105415.