Research

The CFD & HSE Simulation Research Group utilizes advanced numerical techniques to address critical challenges in industrial process safety, occupational health and safety, indoor air quality, air pollution, multiphase flows, chemical reaction engineering, porous scale modelling, and public health. Through rigorous numerical simulations, we provide in-depth understanding and predictive capabilities for complex phenomena across these interconnected domains. Furthermore, we are increasingly incorporating AI/ML algorithms with our numerical data obtained to provide enhanced critical insights, achieve more accurate predictions, faster analysis, and optimized solutions for a wide spectrum of vital industrial and public health issues. This interdisciplinary approach fosters a deeper understanding of complex phenomena and facilitates the development of more effective strategies for enhancing safety, health, and environmental protection.

Industrial Process Safety

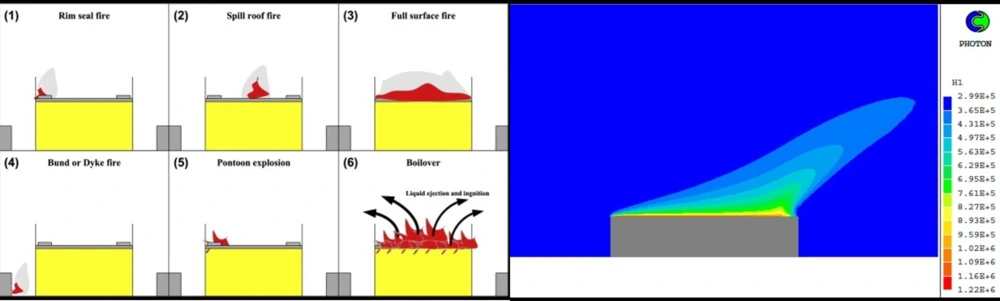

To ensure process safety in the Oil & Gas and Petrochemical industries, we employ a combination of advanced Computational Fluid Dynamics (CFD) tools (Fig.1) and comprehensive Process Hazard Analysis (PHA) methods. Our PHA framework includes established techniques such as checklists, Quantitative Risk Assessment (QRA), HAZOP (Hazard and Operability Study), STAMP (Systems-Theoretic Accident Model and Processes), and STPA (Systems-Theoretic Process Analysis), among others. This powerful combination enables us to simulate and thoroughly analyze potential hazards, including the dispersion of flammable or toxic materials from a release, the progression dynamics of explosions, and the performance of safety barriers and ventilation systems

Figure1:a) Potential tank fire scenarios [1] and b) Enthalpy contours around the tank on fire obtained using the commercial CFD software PHOENICS [2].

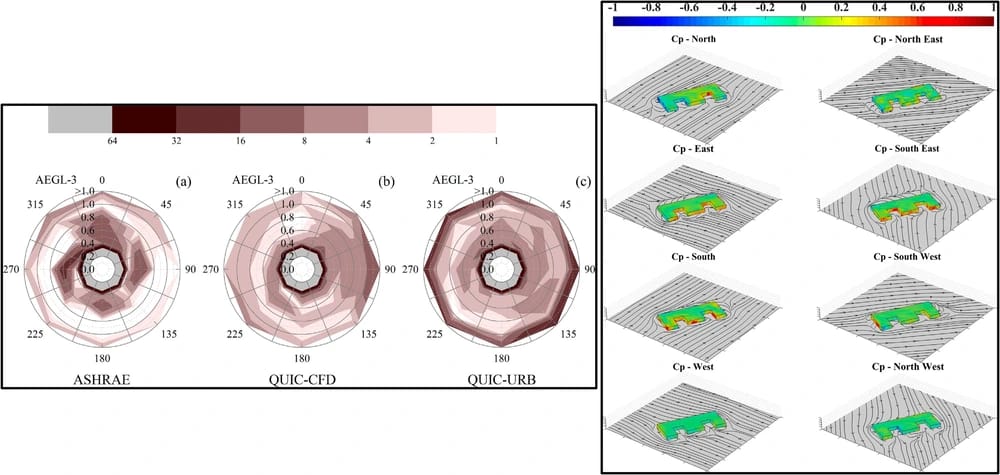

A critical consideration, often posing a higher risk, is the potential for toxic releases occuring outdoors to impact occupants withing nearby indoor environments. The ingress and subsequent entrapment of hazardous gases indoors can lead to significantly accelerated accumulation, potentially reaching lethal dosages more readily than in open-air conditions (Fig. 2). Despite this pronounced risk, there remains a notable lack of data in empirical data and comparative studies regarding appropriate modelling techniques and effective mitigation strategies for indoor exposure. Consequently, we utilize advanced CFD techniqeus to specifically investigate phenomena such as toxic building ingress and to perform rigorous risk assessments based on dose-response methodologies. The proposed methodology will serve as a guide for the improvement of relevant risk assessment tools and future studies.

Figure2:a) Distribution of the AEGL-3 values, for all building rooms, at different wind directions and for the CD-HVAC off-scenario, radius corresponds to the AEGL value and the colour represents the number of rooms with this value for: (a)ASHRAE model. (b) QUIC-CFD model and (c) QUIC-URB model and b) Surface streamlines and Cp for “D5”and 8 different wind directions calculated by QUIC-CFD [3].

Furthermore, we harness the power of AI and ML algorithms to extract deeper insights from our numerical data, enabling advanced hazard identification, predictive risk modeling, and sophisticated scenario analysis. By modelling the fluid dynamics of critical events, we contribute directly to the design of inherently safer processes and developing effective risk mitigation strategies. The strategic integration of AI and ML significantly elevates our process safety capabilities, resulting in safer operations, substantial risk reduction, and enhanced environmental stewardship. This data-driven approach paves the way for a more proactive and effective safety management system.

References

[1]C.D. Argyropoulos, M.N. Christolis, Z. Nivolianitou, N.C. Markatos, A hazards assessment methodology for large liquid hydrocarbon fuel tanks, J. Loss Prevent. Proc. Ind., 25 (2012) 329–335.

[2]C.D. Argyropoulos, M.N. Christolis, Z.S. Nivolianitou, N.C. Markatos, A hazard identification and parametric analysis of toxic pollutants dispersion from large liquid hydrocarbon fuel-tank fires, in: Advances in Energy Research, 2013, pp. 333–371.

[3]C.D. Argyropoulos, A.M. Ashraf, N.C. Markatos, K.E. Kakosimos, Mathematical modelling and computer simulation of toxic gas building infiltration, Process Safety and Environmental Protection, 111 (2017) 687–700.