Research

The CFD & HSE Simulation Research Group utilizes advanced numerical techniques to address critical challenges in industrial process safety, occupational health and safety, indoor air quality, air pollution, multiphase flows, chemical reaction engineering, porous scale modelling, and public health. Through rigorous numerical simulations, we provide in-depth understanding and predictive capabilities for complex phenomena across these interconnected domains. Furthermore, we are increasingly incorporating AI/ML algorithms with our numerical data obtained to provide enhanced critical insights, achieve more accurate predictions, faster analysis, and optimized solutions for a wide spectrum of vital industrial and public health issues. This interdisciplinary approach fosters a deeper understanding of complex phenomena and facilitates the development of more effective strategies for enhancing safety, health, and environmental protection.

Multi-phase flows

In general, the physical mechanisms that govern the multi-phase fows are characterised by great complexity and the derivation of the appropriate equations for their description is more sophisticated than single-phase flows. The configuration of multiple interfacial regions with or without moving boundaries, along with the presence of discontinuities across the interfacial region due to fluid properties, are only some of the great challenges facing the field of multi-phase flows. The most common category of multi-phase flows are two-phase flows and may be divided, regarding the combination of the two phases, in the following subcategories:gas-liquid flows (e.g. oil-gas mixture transportation), gas-solid flows (e.g. fluidized beds), liquid-solid flows (e.g. slurry transportation) and liquid-liquid flows (e.g oil-water transportation).

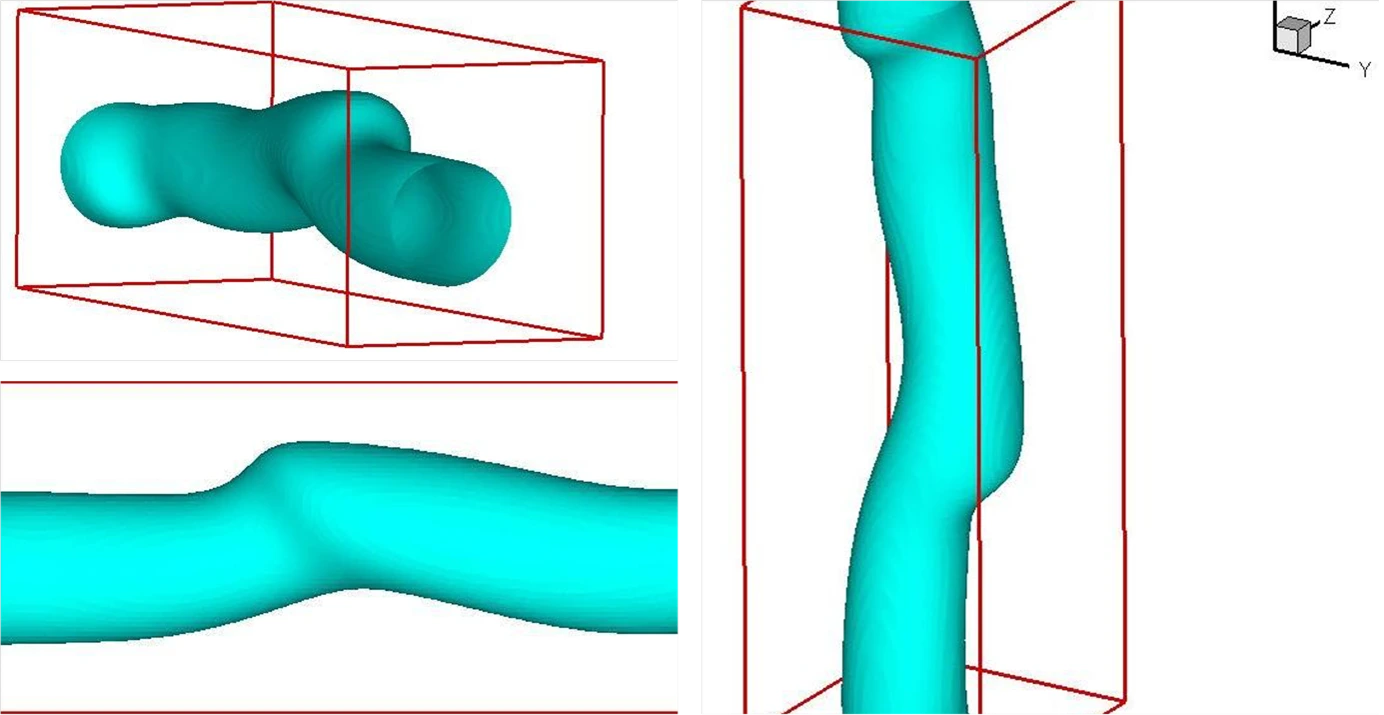

Figure6:Interfacial waves were simulated in order to investigate the travelling waves and the type of the waves (e.g. bamboo, snake, corkscrew, etc.).

Our investigations into multiphase flows involve the numerical simulation of systems where multiple phases (e.g., gas-liquid, liquid-solid) interact. This is crucial for understanding and optimizing a wide range of industrial processes, including chemical reactions, separation processes, and energy systems. Our research is focused on, bubble flow, droplet coalescence, single droplet and interfacial waves in pipe flows (Fig. 6) are some of the considered flows.